lm79 and lm80 standards

Thermal Testing for LED Lights

Thermal Testing for LED Lights, Thermal Testing of LEDs, Thermal testing of road luminaires

If you are looking for Thermal Testing Laboratory for LED Lighting In your Area, ITCIndia NABL Approved Electrical Safety testing Laboratory In India. ITC India one of the best Thermal Testing Laboratory in India, Mumbai, Chennai, Ahmedabad, New Delhi, Pune, Kolkata, Bangalore, Hyderabad, Surat, Visakhapatnam.

ITCIndia “Institute of Testing and Certification India Pvt. Ltd” are a leading testing lab having a NABL accreditation under ELECTRICAL, ELECTRONICS and PHOTOMETRY testing with certificate no. T-3509, T-3570 and T-1811. ITCIndia Lab is following the procedure as required by International Standard IEC 17025 and is already certified for ISO/IEC 17025.

Thermal test is one of the important tests while testing LED luminaries, so we would like to have its basic knowledge.

Thermal test is performed for normal and abnormal conditions. We will peep inside both the conditions respectively.

The motive of thermal test is that the Lamp, part of the luminary, supply wiring, mounting surface should not attain the temperature which can cause injury. The parts like handles should not be too hot to be touched. Same scenario is for the track mounted luminaries are there. Track mounted Luminaries are tested as per clause 12.4.1. Draught proof chamber is specially designed for this particular test. While performing the test, the through wiring and the looping in wiring shall be loaded to the maximum value allowed by the size of the wire, or at a value prescribed by the manufacturer in the installation instructions.

After the test, none of the temperature shall exceed the values given in table 12.1 & 12.2 of IEC 60598-1.

While performing the thermal test in abnormal condition, luminaries are tested in abnormal conditions. The temperature shall not exceed as mentioned in table 12.3, 12.4, and 12.5. If the luminary possesses motor, the test is performed in most critical condition.

Clause 12.6 is applied to the luminary classified for mounting on normally flammable surfaces with a control gear. Clause 12.7 is thermal test in regard to fault conditions in lamp control gear or electronics devices incorporated in thermoplastics luminaries.

Temperature Measurement Data as per client specification

The sample was operated until constant temperatures were obtained. A temperature was considered

constant if the sample was operating for at least three hours and upon three successive readings – taken at

15 minute intervals – were within one degree and were not rising.

Thermocouples were attached at locations described in the results by means of cement made of water

Table-1

| No. of LED’s: | 48 | Ambient Temperature: | 25°C ± 1°C | ||

| Total no. of test points: | 55 | No. of Rows | 4 | ||

| Sr. no. | Measured Temperature at Pt. | Measured Temperature | |||

| Row-1 | |||||

| 1 | LED 1 (Ts) | 56.3 | |||

| 2 | LED 2 (Ts) | 56.7 | |||

| 3 | LED 3 (Ts) | 55.8 | |||

| 4 | LED 4 (Ts) | 55.1 | |||

| 5 | LED 5 (Ts) | 56.4 | |||

| 6 | LED 6 (Ts) | 55.9 | |||

| 7 | LED 7 (Ts) | 55.2 | |||

| 8 | LED 8 (Ts) | 57.1 | |||

| 9 | LED 9 (Ts) | 57.4 | |||

| 10 | LED 10 (Ts) | 56.6 | |||

| 11 | LED 11 (Ts) | 56.9 | |||

| 12 | LED 12 (Ts) | 57.2 | |||

| Row- 2 | |||||

| 13 | LED 13 (Ts) | 54.6 | |||

| 14 | LED 14 (Ts) | 55.8 | |||

| 15 | LED 15 (Ts) | 57.6 | |||

| 16 | LED 16 (Ts) | 57.9 | |||

| 17 | LED 17 (Ts) | 55.5 | |||

| 18 | LED 18 (Ts) | 57.4 | |||

| 19 | LED 19 (Ts) | 56.9 | |||

| 20 | LED 20 (Ts) | 57.6 | |||

| 21 | LED 21 (Ts) | 56.5 | |||

| 22 | LED 22 (Ts) | 57.5 | |||

| 23 | LED 23 (Ts) | 56.3 | |||

| 24 | LED 24 (Ts) | 56.9 | |||

| Row -3 | |||||

| 25 | LED 25 (Ts) | 55.5 | |||

| 26 | LED 26 (Ts) | 54.9 | |||

| 27 | LED 27 (Ts) | 55.9 | |||

| 28 | LED 28 (Ts) | 56.0 | |||

| 29 | LED 29 (Ts) | 56.3 | |||

| 30 | LED 30 (Ts) | 55.9 | |||

| 31 | LED 31 (Ts) | 56.2 | |||

| 32 | LED 32 (Ts) | 54.3 | |||

| 33 | LED 33 (Ts) | 55.2 | |||

| 34 | LED 34 (Ts) | 55.9 | |||

| 35 | LED 35 (Ts) | 56.3 | |||

| 36 | LED 36 (Ts) | 56.8 | |||

| Row- 4 | |||||

| 37 | LED 37 (Ts) | 55.5 | |||

| 38 | LED 38 (Ts) | 55.9 | |||

| 39 | LED 39 (Ts) | 56.1 | |||

| 40 | LED 40 (Ts) | 57.5 | |||

| 41 | LED 41 (Ts) | 56.2 | |||

| 42 | LED 42 (Ts) | 55.9 | |||

| 43 | LED 43 (Ts) | 57.2 | |||

| 44 | LED 44 (Ts) | 57.7 | |||

| 45 | LED 45 (Ts) | 57.3 | |||

| 46 | LED 46 (Ts) | 56.9 | |||

| 47 | LED 47 (Ts) | 57.5 | |||

| 48 | LED 48 (Ts) | 57.8 | |||

| TP Point Pcb -1 | |||||

| 1. | TP | 56.5 | |||

| TP Point Pcb -2 | |||||

| 1. | TP | 55.6 | |||

| TP Point Pcb -3 | |||||

| 1. | TP | 55.9 | |||

| TP Point Pcb -4 | |||||

| 1. | TP | 56.1 | |||

| TP Point Pcb -5 | |||||

| 1. | TP | 56.2 | |||

| TP Point Pcb -6 | |||||

| 1. | TP | 56.9 | |||

| Ballast Tc Test point | |||||

| 1. | Tc | 53.4 | |||

ITC India Pvt. Ltd. is accompanying which possesses the full scope of IEC 60598-1. For any query please write us at …..

If you’re Buyers Demanding for Thermal Testing– Contact Now

Wish this blog post will be help. If you have any other questions, please feel free to contact us. ITCIndia team looking forward work with you and get better together!

Mr. Puneet Sharma | Call: 08196980555 | E-mail: [email protected]

Get Instant Quotations, Fill the Enquiry form:

This entry was posted in Thermal Testing and tagged Advanced thermal characterization improves LED street-light, How to calculate your LED heat sink, How to Measure Thermal Resistance of LED, ies lm 82 12 pdf, led driver testing equipment, led driver testing method, led light testing procedure, led lighting standards testing and certification, LED Luminaire Lifetime: Recommendations for Testing and Reporting, LED Radio/Spectrometric Test, LED Test & Measurement, led testing standards, LED Testing Standards Overview, LED thermal management, LED thermal testing, LED Thermal Testing Report, Lighting Thermal Test Report, lm-79 standard pdf, lm79 and lm80 standards, Report on methods for accelerated aging tests for SSL, Searches related to Thermal Testing for LED Lights, Testing of Power LEDs, Testing of Power LEDs: The Latest Thermal Testing Standards, Thermal Analysis and Testing, Thermal Chambers | Temperature Test, Thermal Management for LED Applications, Thermal management of an led light, thermal shock test report, Thermal test of 30W (25W) high bay light, Thermal Testing, Thermal Testing - Leading Thermal Analysis Experts, Thermal Testing for LED Lights, Thermal Testing for LED Lights in Ahmedabad, Thermal Testing for LED Lights in Bangalore, Thermal Testing for LED Lights in Chennai, Thermal Testing for LED Lights in India, Thermal Testing for LED Lights in Mumbai, Thermal Testing for LED Lights in New Delhi, Thermal Testing for LED Lights in Pune, Thermal Testing in India, Thermal Testing Lab, thermal testing of AC LEDs, Thermal Testing of an Automotive LED Fog Light, Thermal Testing of LEDs, Thermal testing of road luminaires with sodium and LED lamps, Thermal Testing Service, thermal testing standards for high power LEDs, thermal testing | Light & Mirrors.

What are the limitations of LM-79?

What are the limitations of LM-79?

As we all know about the strength of LM 79. Everything has its pros and cons. Let us have a look on the drawbacks of LM 79.

- LM 79 depicts the parameters of the individual products. So the obtained Parameters cannot be used to access alike products.

- Other limitation is the sample size. It does not state any sample size. So, the manufacturer provides only one sample instead of supplying more. This thus increases the vulnerability of lesser quality products.

- This can be used only to determine complete luminary instead of LED used ( as based on absolute photometry) , which can produce different results due to quality of accessories used like glass, thermal effect, lenses etc.

If you’re Buyers Demanding for LM-79 Testing– Contact Now!

Wish this blog post will be help. If you have any other questions, please feel free to contact us. ITCIndia team looking forward work with you and get better together!

Mr. Puneet Sharma | Call: 08196980555 | E-mail: [email protected]

Get Instant Quotations, Fill the Enquiry form:

This entry was posted in LED Bulb Testing, LED Driver Testing, LED Street Light Testing, LED Testing, LED Tube Light Safety Testing, LM 79 Tesing For Street Light As Per IEC 60598-2-3, LM 79 Testing, LM 79 Testing for LED Floodlights and Streetlights, LM 79 Testing in Kolkata West Bengal India, LM 79 Testing Mumbai Maharashtra India, LM-79 Testing Ahmedabad, LM-79 Testing for LED Batten, Lm-79 Testing for LED COB Down light, Lm-79 Testing for LED COB Spot Lights, Lm-79 Testing for LED COB Zoom light, LM-79 Testing for LED DownLight, LM-79 Testing for LED Flood lights, LM-79 Testing for LED Solar Street Light, Lm-79 Testing for Tube Light, LM-79 Testing in Bangalore Karnataka India, Lm-79 testing lab in India, LM-79 Testing on High bay LED lights, LM-79 testing on High Power LED Light Model, LM-79 Testing | LM-79 Test Approved Methods, Photometric Testing, Photometric Training and tagged & TM21, and TM-21, Calculating SSL Performance from LM-79 -ITCIndia, ISTM, istmt, LED Lighting Facts, led lumen maintenance, led testing labs in india, Lm 79, lm 79 80 standards, lm 79 certificate, lm 79 test, lm 79 testing labs in bangalore, lm 79 testing labs in india, lm 79 testing labs in mumbai, lm 80 report, lm-79 and lm-80 report, LM-79 Luminaire Testing Laboratory, lm-79 requirements, lm-79 test procedure, LM-79 Test Report, LM-79 test reports and luminaire LED quality and performance, LM-79 testing, LM-79 Testing - ITCINDIA, Lm-79 testing Ahmedabad, Lm-79 testing Chennai, Lm-79 testing Delhi, Lm-79 testing India, lm-79 testing kolkata, lm-79 testing lab, Lm-79 testing lab in India, Lm-79 testing Mumbai, lm-80, lm79, lm79 and lm80 standards, lm79 and lm80 testing, lm79 report, lm80 certification, lm80 test procedure, luminaire testing, luminaire testing lab, luminaire testing laboratory, Luminaries/LED Product Testing, sample lm79 report, Searches related to What are the limitations of LM-79, tm 21, Understanding IES LM-79 & IES LM-80, Understanding LED tests IES LM-79, What are the limitations of LM-79?, What are the limitations of LM-79? « Electrical Safety Testing.

What are LM 79 Test Outcomes?

What are LM 79 Test Outcomes?

LM-79 is approved test method for electrical and photometric measurements of Solid State Lighting Products. It describes the procedure in measuring total luminous flux, electrical power, luminous intensity distribution, chromaticity under standard conditions. It covers LED based SSL products with control electronics and heat sink incorporated with AC or DC power supply. This does not include LED chips, LED package or LED module but luminaries (fixtures incorporating light source) as well as integrated LED lamps.

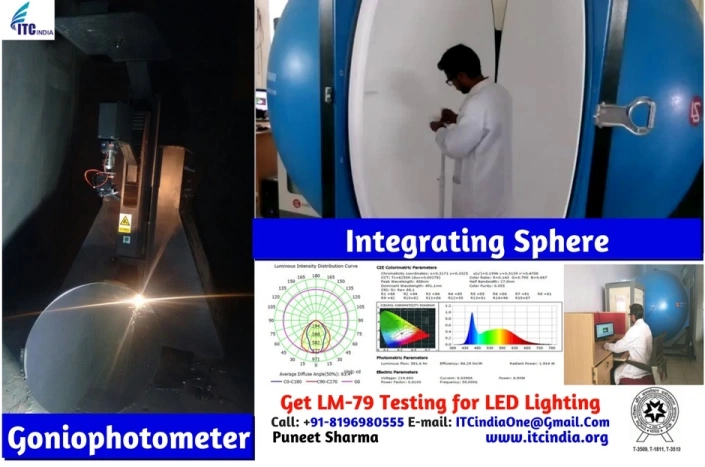

The equipment used in LM-79 is integrated sphere and goniophotometer.

Integrating Sphere Goniophotometer

The test report shall list all significant data for each SSL product tested together with performance data. The outcomes of the LM-79 test are:

- Correction factor applied ( e.g. spectral mismatch, self absorption , intensity distribution etc.)

- Measured total luminous flux( lumen(lm)), input voltage(v), current(a), power(w), Luminous intensity distribution(cd), efficacy(lm/w)

- Color quantities( chromaticity coordinates, CCT, CRI )

- Spectral power distribution

- Bandwidth of spectoradiometer, if spectral distribution and/or color quantities are reported.

- Statement of uncertainties (if required)

- Deviation from standard operating procedures, if any.

Here is the link of a test report issued by our prestigious company. LM 79 Test Outcomes

If you’re Buyers Demanding for LM-79 Testing– Contact Now!

Wish this blog post will be help. If you have any other questions, please feel free to contact us. ITCIndia team looking forward work with you and get better together!

Mr. Puneet Sharma | Call: 08196980555 | E-mail: [email protected]

Get Instant Quotations, Fill the Enquiry form:

This entry was posted in LED Testing, LM 79 Testing and tagged and TM-21, Best LM 79 Testing Lab, CCT and power factor . Contact us Now, Chromaticity coordinates, CRI, Electrical Properties, Get Lm 79 Test Report in 5 days, ies lm-80, Input AC power, Input RMS AC current, Input RMS AC voltage, Input voltage frequency, Instrument solutions for lm-79, Lamps & Luminaires - EMC-EMI Testing lab in Delhi, Lamps & Luminaries |LED Testing lab in Delhi, led light testing laboratory in india, LED Lighting Facts® LED Lumen Maintenance and Warranty Labele, led testing lab in india, LID, list of nabl accredited labs, list of nabl accredited labs for LED testing, list of nabl accredited labs for Lm testing, List of NABL Labs in India, Lm 79, lm 79 80 standards, LM 79 testing by NABL - Accredited lab in just 5 days, lm 79 testing labs in india, lm 79 testing labs in maharashtra, lm 80 report, lm 80 standard pdf, LM-79 LM-80 Technical Report, LM-79 Test Report, LM-79 test reports and luminaire LED quality and performance, LM-79 Testing Laboratory, lm-79 Testing | lm 79 test report - Electrical Safety Testing Lab ITC India, lm-80, lm79 and lm80 standards, LM79-08 Approved Method, Lumens, luminaries testing lab, Luminous efficacy (lumens/W), Luminous flux (lumens), Luminous intensity distribution (candelas), nabl accredited labs for LED testing, nabl approved lab list, NABL Lab for lm 79 testing, National Accreditation Board for Testing and Calibration Laboratories, Photometric lab, Photometric Properties, photometric testing labs, Photometric Testing: Lamp - LED - Luminaire Testing, sample lm79 report, Searches related to What are LM 79 Test Outcomes, SPECIFIC CRITERIA for PHOTOMETRY TESTING LABORATORIES, Testing efficient luminaires and LED retrofit lamps, tm 21, tm-21 led, Top lm 79 testing lab in Ahmedabad, Top lm 79 testing lab in bangalore, Top lm 79 testing lab in india, Top lm 79 testing lab in Mumbai, Top lm 79 testing lab in New Delhi, Top lm 79 testing lab in pune, Understanding LED tests IES LM-79, What are LM 79 Test Outcomes?.

How LM-79 testing can help assess LED luminary quality and performance?

How LM-79 testing can help assess LED luminary quality and performance?

We all believe in buying quality products. Discovery of LED is boon to our world. LED has replaced all the traditional lightning systems because of its quality, life and performance. Manufacturers are switching from manufacturing traditional lightning to produce LED lighting. Many of the manufacturers are making unsubstantial claims regarding colour quality, luminous flux (lm), efficacy (lm/w) and general quality. This can Lead to LED degradation. To ensure quality, a series of test has to be performed on LED luminaries for its long term survival. This is served by LM 79 test method. It is not only the LED but the whole SSL has to qualify all the tests.

For special purpose, it may be useful to determine the characteristics of SSL products when they are operated at other than standard conditions described in the approved method.

Photometric testing includes measurements of total radiant flux, luminous flux, Efficacy (lm/w), chromaticity, correlated color temperature (CCT), and color rendering index (CRI), Light Intensity Distribution (cd). Radiant flux, expressed in watts, is a measurement of the total power of electromagnetic radiation (light) emitted from the luminary or lamp. Luminous flux is a weighted measurement based on human visual perception.

The above measured parameters help to access the LED luminary quality and performance.

ITC india Pvt Ltd is a leading company to test LM 79, company has both the highly accurate equipments “The Integrating Sphere” & “ The Goniophotometer” installed at its premises.

ITC india is a NABL accredited lab having full scope of LM 79( certificate no. T-3510.)

If you’re Buyers Demanding for LED Luminaries Lamps Testing– Contact Now!

Wish this blog post will be help. If you have any other questions, please feel free to contact us. ITCIndia team looking forward work with you and get better together!

Mr. Puneet Sharma | Call: 08196980555 | E-mail: [email protected]

Get Instant Quotations, Fill the Enquiry form:

This entry was posted in LED Testing, LM 79 Testing, Luminaries LED Product Testing and tagged Assessment of Advanced Solid-State Lighting, Assessment of Solid-State Lighting Products, Energy-saving lighting testing, How to check in LM, LED Lab Test, LED Luminaire Reliability, LED Luminaire Testing to Include LM-79 Photometric, LED Street Lighting Assessment, LED Test & Measurement, list of approved testing laboratories in india for LM, list of approved testing labs in india for LM, list of labs under lm, list of testing laboratories in india for LM, LM 79 Test Laboratory - LED/SSL Luminaires, lm 79 testing labs in india, lm 80 report, LM Test Labs, LM testing laboratories, lm79 and lm80 standards, Most Comprehensive LED Luminaire Test, NABL approved test labs for LM, need/requirement in LM, need/requirement in LM Testing, need/requirement under LM, need/requirement under LM Testing, Performance measurement of lamps and luminaires, performance testing of lighting products, sample lm79 report, Understanding LM-80: Measuring Lumen Maintenance of LED Light, what are the Parameters Required under LM testing, WHAT is LM Testing, what to check in LM, who do LM Tests/testing, Who will do testing in LM, Why testing is necessary under LM, Why to check in LM.

Lm-79 Testing | Lm 79 test report | Lm 79 test procedure India

LM-79 Testing, Lm 79 Test report, LM 79 Test procedure, India

ITC India is a NABL accredited laboratory in discipline of Electrical (T-1811), Electronics (T-3509) and photometry (T-3510), serving its satisfied customers for last 5 years. Laboratory is fully equipped with the highly accurate Machines to test LM 79. It owns a Integrating sphere as well as the Goniophotometer. Qualified and experienced engineer are appointed to perform the desired tests.

Gone are those days when we use incandescence (tungsten filament) or fluorescent (mercury atoms) bulb. They are replaced by LED’s Now; this is an era of SSL (LED) as ……There is innumerable reason for the rise in LED’s which cannot be counted on finger tips. It is beneficial to both USERS as well as to the nation. Its superior features make it so promising that one cannot deny using LED’s. The features of LED’s are, its low power consumption, digitally controllable, Low maintenance, Ultra long source life, no UV or IR radiations, No mercury content. SSL uses semiconductors material to convert Electricity into light. LED’s are non carbon materials.

Efficacy is the quality parameter for LED: it is measure in Lumen per watt. Higher efficacy means high energy efficient. Another quality factor is lifetime and last but not the least is Color rendering Index (CRI). CRI measures the ability of light source to reproduce the color of various objects in comparison with natural light source.

How LM-79 testing can help assess LED luminaries quality and performance?

AS LM79 report provides you with the Photometric as well as electrical parameters with a spectrum Test report. The photometric parameters are luminous flux, Efficacy and Radiant Power, CIE colorimetric Parameters (coordinates Color rendering Index (CRI), color coordinate Temperature (CCT) Duv Value, and light Intensity Distribution .Current, Voltage, Power factor, Power and frequency are the electrical parameters. It Focus on the efficiency and CRI, which are the quality parameter. Efficiency measures how much electrical energy is converting into light energy. Power factor is another electrical metric for LED driver performance and often a key parameter for street lighting due to the large number of these luminaries connected to the power grid. As far as for lifetime, LM 80 covers that part.

What is the LM-79 test methodology?

LM 79 is approved method to test Photometric and electrical measurements of Solid state lightning. It describes the procedure and precaution to be observed during measurements. This approved method covers LED based SSL products with control electronics and heat sinks incorporated, that is , those devices that require only AC main power or a DC voltage power supply to operate. This document does not covers SSL products that require external operating circuits, or external heat sink. LM 79 covers SSL product in a form of luminaries (fixture incorporating light source) as well as integrated LED lamps.

Why do we need it?

We need it to access the quality and other parameters due to increasing competition in the market. It provides the efficiency and power factor.

How is LM-79 different from other test methods used for conventional lighting products?

This approved method is a guide developed for the measurements of SSL products. While many other standards for photometric measurements of light sources and luminaries are available, these standards are separated for measurements of lamps and luminaries. Since the current SSL products are in the form of luminaries or lamps, and LED light source in luminaries are not easily separated as replaceable lamps, these existing standard cannot be applied directly to SSL products. This necessitates the use of absolute photometry. This test method uses absolute photometry where as other standard uses relative photometry in short.

Now lets us clear about relative and absolute photometry.

| S.NO | Absolute Photometry | Relative Photometry |

| 1 | Total lumen output of a luminary (bulb with fixture) | Total Lumen output of a bare lamp is measured. |

| 2 | Method used to measure LED performance. | Method used to measure Bare bulb and system performance. |

| 3 | Output is relative to an easy measured condition.

|

Output is measured in calibrated units under specific operating and environment conditions, ambient temperature, input voltage and orientation. |

| 4 | Specific lamp performance does not matter,

|

Lamps and system performance matters.

|

| 5 | Use for SSL products | For NON SSL products |

What are the LM-79 test outcomes?

The outcome of the LM 79 is the REPORT providing all the required parameters as per LM 79.

They are ……

- CIE colorimetric parameters

- Chromaticity coordinate (x)

- Chromaticity coordinate (y)

- Chromaticity coordinate (u’)

- Chromaticity coordinate (v)

- Chromaticity coordinate (v’)

- Correlated color temperature(Tc)

- Duv Value

- Color Rendering Index(Ra)

- Photometric Parameters

- Luminous Flux( Lumen)

- Luminous Efficacy( Lm/W)

- Radiant Power

- Electric Parameters

- Input Voltage(V)

- Current(A)

- Power(W)

- Power Factor

- Frequency(Hz)

- Test information

Ambient Temperature, Stabilization Time, Total Operating Time, Sphere Dia, Photometric method or instrument used Wavelength range in nm of spectroradiometer.

Along with this a SPECTRUM TEST REPORT is also issued.

What are the limitations of LM-79?

- Chips, Packages, or Modules requiring external heat sinks or operating circuits are not covered

- Does not state the sampling size.

Is there a future scope for improvement in the LM-79 test?

Yes of course, there is always a scope for improvement in all areas.

Range/criteria of acceptance of CCT, CRI & Lumens may be defining to establish a harmonization of parameters globally.

Top Searches related to LM 79 Tests for LED Tube Lights:

LM-79 Testing Report LM-79 Testing Service in India

If you’re Buyers Demanding for LM-79 Testing– Contact Now!

ITC India has around 5000 clients from LED lighting division from All over India.

Get LM 79 Test Report, You can Please feel free to Ask for Quotation.

Mr. Puneet Sharma | Call: 08196980555 | E-mail: [email protected]

Get Instant Quotations, Fill the Enquiry form:

This entry was posted in LM 79 Testing, LM 79 Testing in Kolkata West Bengal India, LM 79 Testing Mumbai Maharashtra India, LM-79 Testing Ahmedabad, LM-79 Testing in Bangalore Karnataka India, Lm-79 testing lab in India, LM-79 Testing | LM-79 Test Approved Methods and tagged Affordable Places for Lm 79 testing, Ahmedabad, Ask for Lm-79 Testing, Bengaluru, Best LM 79 Test Laboratory, Best Places for Lm 79 testing, Bhubaneshwar, Chennai, Coimbatore, competitive and Affordable cost for Lm 79 testing, competitive and Affordable cost to get Lm 79 testing, competitive and Affordable price for Lm 79 testing, competitive and Affordable price to get Lm 79 testing, Delhi, Door steps Lm-79 Testing Facilities, Excellent Lm-79 Testing Laboratory, Excellent Lm-79 Testing service, Excllent Lm-79 Testing Laboratory, Get Cheap Lm79 Testing, Get Lm-79 Test Report, Get Lm-79 Testing in 2 days, Get Lm-79 Testing in affordable cost, Get Lm-79 Testing in Affordable price, Get Lm-79 Testing in nominal cost, Get your product tested (Lm-79 Testing) in Affordable price, Gurgaon, Hassle Free Lm-79 Testing at your Door steps, Hassle Free Lm-79 Testing services in Tricity, Hassle Free Lm-79 Testing services in your area, Hyderabad, Indore, Jaipur, Kochi, Kolkata, Kozhikode (Calicut), LED testing (LM-79) at your Door steps, LM 79 Test Laboratory, LM 79 testing Expert, LM 79 Testing for LED lights at your Door steps, LM 79 testing in competitive, LM 79 testing in Lower Cost, lm 79 testing labs in india, LM 79 testing Professional, lm-79 and lm-80, lm-79 standard, lm-79 test procedure, LM-79 Test Report, LM-79 testing, Lm-79 Testing Facilities at your Door steps, lm-80, lm79 and lm80 standards, LM79 Testing, lm80 testing, Lumen Maintenance 79 for LED lights at your Door steps, Lumen Maintenance 79 Testing for LED lights at your Door steps, Mangalore, Mumbai, Nagpur, Noida, Online Get Cheap Lm79 Testing, Professional LM 79 test, Pune, request for Lm-79 Testing, Searches related to lm-79 testing, Surat, Understanding LM-79 Reports, Vadodara, Visakhapatnam.