Cables EMC Electromagnetic Compatibility Testing

Are You looking for Cables EMC Electromagnetic Compatibility Testing labs in India?

Advanced Cables EMC Testing Laboratory

If you are looking for a Cables EMC Testing Laboratory in India, then you are in the right place. ITC India Can Help You! ITC India one of the best Cables EMC Testing Service Providers in India. ITCIndia Can do Cables EMC Testing as per IEC / IS, EN, ISO, BIS Standard.

Know the testing Fees against standard IEC/ IS for Cables – Email Now! [email protected]

ITC India is having best Cables EMC Testing Labs to test Cables. We provide all types of testing related to Cables. Call at 08196980555 for Cables EMC Testing Laboratories.

ITC India Electrical safety testing lab provides Cables EMC Testing in India, Mumbai, Ahmedabad, Chennai, New Delhi, Bangalore, Pune, Hyderabad and all over the World.

Cables that are used in Electronic Equipment play a significant role in the overall EMC situation either in a positive or negative way…

The electromagnetic compatibility (EMC) principle of cables is that communication signals should be kept inside the cables, and outside electromagnetic fields should not disturb the data transmission inside the cable.

The requirement for COAXIAL Cables designed for Broadcast and communication Technology to avoid interference problem

| Sr. No | Metrics | |

| 1 | Impedance | Less than 5 mΩ/m from 5 to 30 MHZ |

| 2 | Screening Attenuation | 85 dB from 30 – 1000MHZ( Screening Class A , in IEC 61196-6 ) |

Majority of Coaxial cables available in the market do not full fill the above said the requirement that lead to EMC and Mechanical weakness. Thus, affects the immunity of the equipment.

Why choose ITCIndia For Cables EMC Testing?

ITCIndia is a leading provider of comprehensive testing services for electrical and LED lighting products. Our global network of technical experts, combined with our state of the art testing laboratories, assure a single-source solution for meeting all applicable requirements, standards and voluntary schemes. And ITCIndia technical professionals are actively involved in international advisory boards and standards development activities, ensuring the most up to date knowledge of current and changing requirements.

Represented in over 5 locations in India, ITCIndia has an unsurpassed track record of meeting and exceeding the requirements and expectations of our client companies. The ITCIndia brand and our distinctive blue octagon mark are instantly recognized around the globe as symbols of quality and safety Testing and will increase customer confidence in your brand.

ITCIndia can assist companies in low-cost life testing and evaluating of their products for pre-compliance and compliance testing to schemes such as The Carbon Trust Enhanced Carbon Allowance

If Your Buyers Demanding for Cables EMC Testing.– Contact Now!

Kindly send us the following Details, So that we can provide you with a quotation for the same:

- Product Name, Technical Specifications, and Brochure

- Product Images

- Total Number of Samples Required: 2

Wish this blog post will help. If you have any other questions, please feel free to contact us. ITCIndia team looking forward to working with you and get better together!

Mr Puneet Sharma | Call: 08196980555 | E-mail: [email protected]

Get Instant Quotations, Fill the Enquiry form:

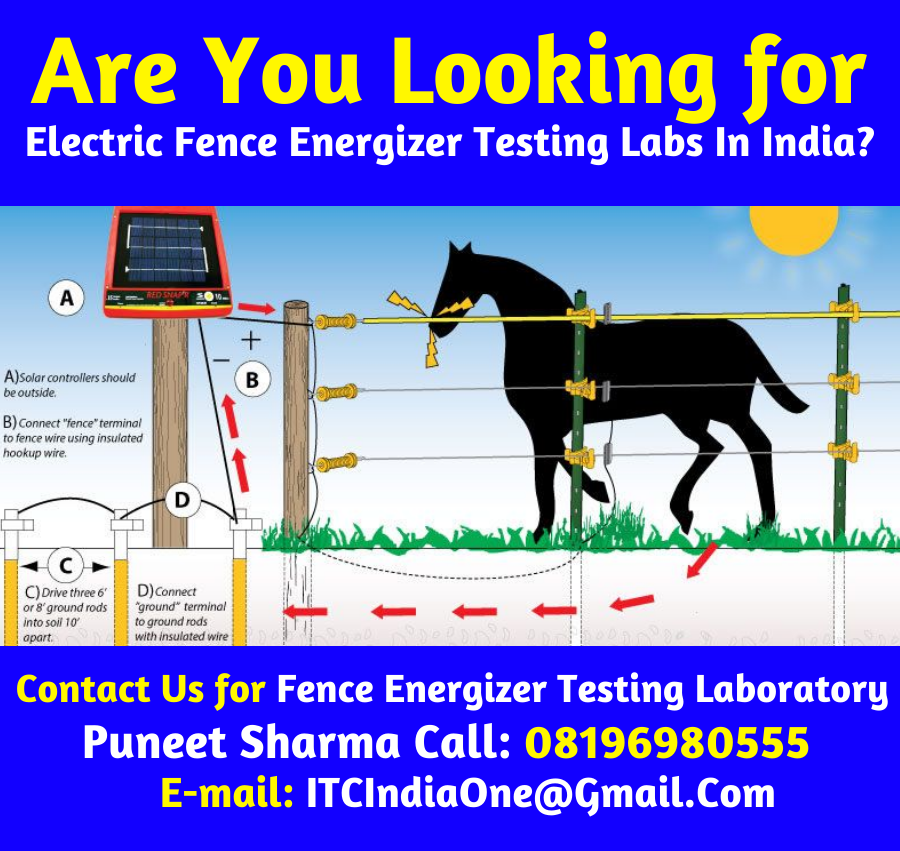

Are You looking for Electric Fence Energizer Testing Laboratory?

Advanced Electric Fence Energizer Testing Laboratory

If you are looking for an Electric Fence Energizer Testing Laboratory in India, then you are in the right place. ITC India Can Help You! ITC India one of the best Electric Fence Energizer Testing Service Providers in India. ITCIndia Can do Solar Electric Fence Energizer Testing as per IEC 60335-2-79/ IS 302-2-76, EN, ISO, BIS Standard.

Know the testing Fees against standard IEC 60335-2-79/ IS 302-2-76 for Electric Fence Energizer – Email Now! [email protected]

ITC India is having best Solar Electric Fence Energizer Testing Labs to test Fence Energizer. We provide all types of testing related to Fence Energizer. Call at 08196980555 for Fence Energizer Testing Laboratories.

ITC India Electrical safety testing lab provides Electric Fence Energizer Testing in India, Mumbai, Ahmedabad, Chennai, New Delhi, Bangalore, Pune, Hyderabad and all over the World.

Why choose ITCIndia For Electric Fence Energizer Testing?

ITCIndia is a leading provider of comprehensive testing services for electrical and LED lighting products. Our global network of technical experts, combined with our state of the art testing laboratories, assure a single-source solution for meeting all applicable requirements, standards and voluntary schemes. And ITCIndia technical professionals are actively involved in international advisory boards and standards development activities, ensuring the most up to date knowledge of current and changing requirements.

Represented in over 5 locations in India, ITCIndia has an unsurpassed track record of meeting and exceeding the requirements and expectations of our client companies. The ITCIndia brand and our distinctive blue octagon mark are instantly recognized around the globe as symbols of quality and safety Testing and will increase customer confidence in your brand.

ITCIndia can assist companies in low-cost life testing and evaluating of their products for pre-compliance and compliance testing to schemes such as The Carbon Trust Enhanced Carbon Allowance

If Your Buyers Demanding for Electric Fence Energizer Testing.– Contact Now!

Kindly send us the following Details, So that we can provide you with a quotation for the same:

- Product Name, Technical Specifications, and Brochure

- Product Images

- Total Number of Samples Required: 2

Wish this blog post will help. If you have any other questions, please feel free to contact us. ITCIndia team looking forward to working with you and get better together!

Mr Puneet Sharma | Call: 08196980555 | E-mail: [email protected]

Get Instant Quotations, Fill the Enquiry form:

Are You Looking for Photometric Testing Laboratory in India?

Are You Looking for Photometric Testing in India?

If you are looking for a Photometric Testing Laboratory in India, ITC India Can Help You! ITC India one of the best photometry Testing Service Providers in India. ITCIndia Can do Photometric Testing as per IEC, EN, ISO, BIS Standard

ITCIndia is India’s specialist LED and SSL lighting Photometric Testing laboratory. We provide all types of testing related to LED Lights. Call at 08196980555 for Photometric Testing Laboratories. ITCIndia Photometry test lab according to EN13032, EN13032-4, color, Photobiological safety EN 62471 and IEC.

Our Photometric lighting laboratory has already implemented quality management according to EN ISO/IEC 17025. Thereby, ITCIndia operates the first accredited and manufacturer-independent LED lighting laboratory in India.

We validate your LED lighting competence parameters and reveal how your Photometric products perform in real life. With our precision instruments, ITCIndia can determine all photometric parameters. We always keep our lab up to date with the latest technological developments and standards. ITCIndia quality management ensures the highest degree of accuracy and reproducibility in operation.

ITCIndia Advanced Photometric Testing laboratory can do testing of LED lamps, headlights, tail lights, LED Bulbs, Wall Lights, Ceiling Lights, Tube Lights, Spot Lights, Down Lights, Desk/Table Lights, Suspension Lights, Decor Lights, COB Lights, Landscape Lights, Flood Lights, Road Lights, Recess Mounted LED Luminaires, Suspension Luminaire, Task Lights (Furniture Integrated), Desk Lights, Batten Lights, Surface Mounted Luminaires, Linear Lamps, Flexible Strip Lights, Outdoor Luminaires, Street Lights, Flexi Strips, Highbay Luminaires, Deco Lights, LED Glass Bulbs, Panel Lights, Surface Lights, Parking Lights, Ceiling Lights, Track Lights, Multibox Lights, House Lights, Strip Lights, Moisture-Proof Light, Beam/Flood Lights, Decorative & Garden Lights, Full Glass LED Lamps, LED Mini Lamp, LED Night Lamp, Linear Lamps, Pendant Lights, direction of indicators, reflectors, plastic lens, etc.

Why choose ITCIndia For photometry Testing?

ITCIndia is a leading provider of comprehensive testing services for electrical and LED lighting products. Our global network of technical experts, combined with our state of the art testing laboratories, assure a single-source solution for meeting all applicable requirements, standards and voluntary schemes. And ITCIndia technical professionals are actively involved in international advisory boards and standards development activities, ensuring the most up to date knowledge of current and changing requirements.

Represented in over 5 locations in India, ITCIndia has an unsurpassed track record of meeting and exceeding the requirements and expectations of our client companies. The ITCIndia brand and our distinctive blue octagon mark are instantly recognized around the globe as symbols of quality and safety Testing and will increase customer confidence in your brand.

ITCIndia can assist companies in low-cost life testing and evaluating of their products for pre-compliance and compliance testing to schemes such as The Carbon Trust Enhanced Carbon Allowance

If Your Buyers Demanding for photometry Testing.

– Contact Now!

Kindly send us the following Details, So that we can provide you with a quotation for the same:

- Product Name, Technical Specifications, and Brochure

- Product Images

- Total Number of Samples Required: 2

Wish this blog post will help. If you have any other questions, please feel free to contact us. ITCIndia team looking forward to working with you and get better together!

Mr Puneet Sharma | Call: 08196980555 | E-mail: [email protected]

Get Instant Quotations, Fill the Enquiry form:

Searches related to Photometric Testing Lab:

- photometric testing definition

- photometry blood test

- photometric measurement

- lighting flux testing frequency

- lighting flux testing frequency

- lm 79 standard pdf

- lm82 test report

- led driver testing method

- led street light test report

- lm 79 test report sample

- photometric testing labs

- photometric testing definition

- photometry blood test

- photometric test for led light

- photometric measurement equipment

- ITCIndia lab testing

- Advanced Photometric Testing Lab

Hydraulic Baling Machine testing as Per IS 302

Are You Looking for Hydraulic Baling Machine testing as Per IS 302 in India?

If you are looking for a Hydraulic Baling Machine Testing according to IS 302 Standards in India, ITC India Can Help You! ITC India one of the best IS 302 Testing Service Providers in India. ITCIndia Can do Hydraulic Baling Machine Testing as per IEC, EN, ISO, BIS Standard

ITCIndia promises to deliver perfection with every product by its evaluation and assessment techniques designed with a higher degree of professional competence. Along with its existing abilities and a strong quality system, its certifications from the BIS ensure that standardized products have gone under surveillance carried out by qualified professionals only.

On this blog, I am not just going to pitch you to hire us for our Hydraulic Baling Machine Testing services but also going to provide a lot of valuable information on what, why and how we can do Hydraulic Baling Machine Testing as per IEC, EN, ISO, BIS Standard. Call on 08196980555 for IS 302 Testing laboratories.

IS 302 certification mandatory for Hydraulic Baling Machine? Yes IS 302 is mandatory For Hydraulic Baling Machine if you are looking for bis approved IS 302 testing Labs in India then ITCIndia One of The Best BIS Approved Laboratory, ITCIndia can do Hydraulic Baling Machine testing and certification with reasonable cost.

Why choose ITCIndia For IS 302 Testing?

ITCIndia is a leading provider of comprehensive testing services for electrical and LED lighting products. Our global network of technical experts, combined with our state of the art testing laboratories, assure a single-source solution for meeting all applicable requirements, standards and voluntary schemes. And ITCIndia technical professionals are actively involved in international advisory boards and standards development activities, ensuring the most up to date knowledge of current and changing requirements.

Represented in over 5 locations in India, ITCIndia has an unsurpassed track record of meeting and exceeding the requirements and expectations of our client companies. The ITCIndia brand and our distinctive blue octagon mark are instantly recognized around the globe as symbols of quality and safety Testing and will increase customer confidence in your brand.

ITCIndia can assist companies in low-cost life testing and evaluating of their products for pre-compliance and compliance testing to schemes such as The Carbon Trust Enhanced Carbon Allowance

If Your Buyers Demanding for ELECTRICAL SAFETY AS PER IS 302.

– Contact Now!

Kindly send us the following Details, So that we can provide you with a quotation for the same:

- Product Name, Technical Specifications, and Brochure

- Product Images

- Total Number of Samples Required: 2

Wish this blog post will help. If you have any other questions, please feel free to contact us. ITCIndia team looking forward to working with you and get better together!

Mr Puneet Sharma | Call: 08196980555 | E-mail: [email protected]

Get Instant Quotations, Fill the Enquiry form:

CISPR 11 Testing Labs – EN 55011 Testing Laboratories

ITCIndia CISPR 11 testing Laboratory helps your Medical equipment comply with EN 55011 and CISPR 11 standards and reach world markets across. ITC India is having best CISPR 11 Testing Labs to test LED. We provide all types of testing related to CISPR. Call at 08196980555 for CISPR 11 Testing Laboratories.

CISPR 11/ EN 55011

Amendment 2

Industrial, scientific and medical (ISM) radio-frequency equipment – Electromagnetic disturbance characteristics – Limits and methods of measurement

CISPR 11 is a broadly used international standard for electromagnetic compatibility within Europe for electromagnetic emissions or disturbances from Industrial, Scientific, and Medical, ISM, Equipment. CISPR 11 is conserved by CISPR: the International Special Committee on Radio Interference. It has grown from a simple document to a complex document involving a number of types of products

CISPR 11 applies to a very huge variety of equipment including everything from Wi-Fi systems, microwaves through to arc welders, all of which fall into the industrial, scientific and medical category which can use the ISM license-free bands like 2.4 GHz.

CISPR 11, EN 55011 is a standard covering radiated and conducted emissions. Most products will require an assessment of immunity standards, such as EN 61326-1: Electrical equipment for measurement, control and laboratory use; or EN 61000-6-2: Generic Standards Immunity for industrial environments.

It has grown from measuring products at a larger distance (100 meters and 30 meters) for Class A Equipment to measuring them at 3 meters. Class B equipment measurement distances have seen an equivalent degradation of “far-field” radiated emission measurements. This steady erosion of the “laws of physics” is worrisome and a trend to reverse this erosion is overdue in the engineering field of EMC and the EMC Standards arena.

List of tests

Emission Tests |

|

| CISPR 11 | Radiated emissions |

| Conducted emissions input power | |

| IEC 61000-3-2 | Harmonic current emissions |

| IEC 61000-3-3 | Voltage fluctuation & flicker |

Immunity Tests |

|

| IEC 61000-4-2 | Electrostatic discharge immunity test |

| IEC 61000-4-3 | Radiated, radio-frequency, electromagnetic field immunity test |

| IEC 61000-4-4 | Immunity to Electrical Fast Transient |

| IEC 61000-4-5 | Immunity to Surges |

| IEC 61000-4-6 | Immunity to Conducted Disturbances |

| IEC 61000-4-8 | Power frequency magnetic immunity test |

| IEC 61000-4-9 | Pulse magnetic field immunity test |

| IEC 61000-4-11 | Voltage dips |

| IEC 61000-4-11 | Voltage interruptions |

If Your Buyers Demanding for CISPR 11 Testing – Contact Now!

Kindly send us the following Details, So that we can provide you with a quotation for the same:

- Product Name, Technical Specifications, and Brochure

- Product Images

- Total Number of Samples Required: 2

Wish this blog post will help. If you have any other questions, please feel free to contact us. ITCIndia team looking forward to working with you and get better together!

Mr Puneet Sharma | Call: 08196980555 | E-mail: [email protected]

Get Instant Quotations, Fill the Enquiry form:

CISPR 32 Testing Labs – EN 55032 Testing Laboratories

ITCIndia CISPR 32 testing Laboratory helps your multimedia equipment comply with EN 55032 and CISPR 32 standards and reach world markets across. ITC India is having best CISPR 32 Testing Labs to test LED. We provide all types of testing related to CISPR. Call at 08196980555 for CISPR 32 Testing Laboratories.

CISPR 32/ EN 55032

CISPR 32 is a discrete standard formed for Multimedia Equipment having a rated AC or DC supply voltage not exceeding 600 V, but equipment within the scope of CISPR 22 or CISPR 13 is also within the scope of this publication. It incorporates a range of functions which include those in ITE (Information technology), broadcasting, audio, and video equipment. It also includes entertainment lighting control equipment.

In this contemporary world, ITE performs many different functions, features, and capability which were assessed by different compliance standards but now CISPR 32 is a single standard which addresses the case where all different features are integrated instead of having separate compliance standards. This standard is adopted by the European Union.

Two classes of End-User Terminal Equipment Under Test EUT (Class A and Class B) are considered.

The aims of the standard are:

- To establish requirements which provide an adequate level of protection of the radio spectrum allowing radio services to operate as intended in the frequency range 9 kHz to 400 GHz;

- To specify procedures to ensure the reproducibility of measurement and the repeatability of results.

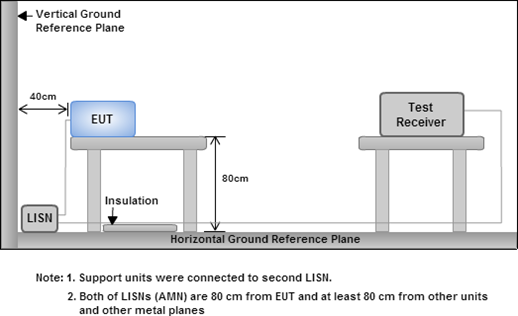

Conducted Emissions from the AC mains power ports

Test set up

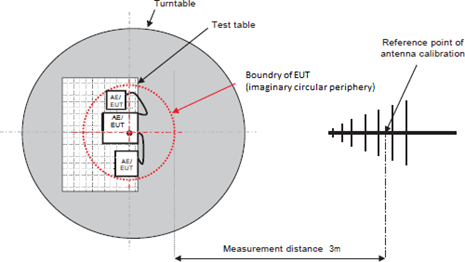

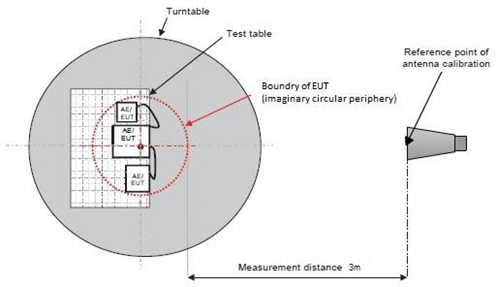

Radiated Emission- Test set up

Radiated Emissions below 1 GHz

Radiated Emissions above 1 GHz

If Your Buyers Demanding for CISPR 32 Testing – Contact Now!

Kindly send us the following Details, So that we can provide you with a quotation for the same:

- Product Name, Technical Specifications, and Brochure

- Product Images

- Total Number of Samples Required: 2

Wish this blog post will help. If you have any other questions, please feel free to contact us. ITCIndia team looking forward to working with you and get better together!

Mr Puneet Sharma | Call: 08196980555 | E-mail: [email protected]

Get Instant Quotations, Fill the Enquiry form:

CISPR 15 Testing Labs – CISPR 15 Testing Laboratories

ITC India is having best CISPR 15 Testing Labs to test LED. We provide all types of testing related to CISPR. Call at 08196980555 for CISPR 15 Testing Laboratories.

CISPR 15

LIMITS AND METHODS OF MEASUREMENT OF RADIO DISTURBANCE CHARACTERISTICS OF ELECTRICAL LIGHTING AND SIMILAR EQUIPMENT

Reference standards for Immunity test in CISPR 15

| S. N | Tests | Standard | Title |

| 1 | Electrostatic Disruption

This test simulates electrostatic events and evaluates the ability of the EUT to tolerate such events. Testing is performed in accordance with IEC/EN 61000-4-2. All accessible enclosure surfaces and ports are evaluated unless specified as a static-sensitive surface. |

IEC 61000-4-2: 2008

ESD Immunity

|

Electromagnetic Compatibility—Testing and measurement techniques – Electrostatic discharge immunity test |

| 2 | Electromagnetic Susceptibility

The Electromagnetic Susceptibility test exposes the equipment under test to a calibrated uniform field of radiated electromagnetic energy. The EUT is continuously monitored while exposed to the required frequency range and field strength. The test chamber, radiating antennas, and calibrated fields meet the requirements of referenced standards |

IEC 61000-4-3: 1996

Radio Frequency Immunity |

Electromagnetic Compatibility—Testing and measurement techniques – Radiated radiofrequency electromagnetic field immunity test |

| 3 | Electrical Fast Transient

This test injects a transient/burst interference onto the Mains input power supply and signal I/O lines. The EUT and peripherals are placed on a non-conductive support platform, 10cm above the test ground plane. The EUT is monitored for disturbances during the required exposure time of positive and negative bursts |

IEC 61000-4-4: 1995-01 Electrical Fast Transient Immunity | Electromagnetic Compatibility—Testing and measurement techniques – Electrical fast transient/burst immunity |

| 4 | Lighting Surge

This test simulates a lightning event by inducing transients onto the AC/DC power supply lines in common and differential mode. Testing is performed in accordance with IEC/EN 61000-4-5. The product-specific standard determines the minimum requirement for the exposure to surge transient levels |

IEC 61000-4-5: 1995-02 Surge Immunity | Electromagnetic Compatibility—Testing and measurement techniques – Surge immunity test |

| 5 | Conducted RF Immunity

This test injects a disturbance directly onto AC/DC power. Testing is performed in accordance with IEC/EN 61000-4-6. The product-specific standard sets the level, duration, and the frequency range to apply. |

IEC 61000-4-6: 1996-04 RF Common Mode Immunity | Electromagnetic Compatibility—Testing and measurement techniques – Immunity to conducted disturbances, induced by radio-frequency fields |

| 6 | Power Disturbance

This test subjects the EUT to power network faults and “brownouts”. Testing is performed in accordance with IEC/EN 61000-4-11. The EUT is powered up to a nominal voltage, and then software controlled voltage dips and interruptions are introduced |

IEC61000-4-11: 1994-06

Voltage Dips and Short Interruptions |

Electromagnetic Compatibility—Testing and measurement techniques – Voltage dips, short interruptions and voltage variations immunity tests |

Device Performance Criteria for Immunity Tests

- Criterion A – The equipment shall continue to operate as intended without operator intervention. No degradation of performance or loss of function is allowed below a performance level specified by the manufacturer when the equipment is used as intended. The performance level may be replaced by a permissible loss of performance. If the minimum performance level or the permissible performance loss is not specified by the manufacturer, then either of these may be derived from the product description and documentation, and by what the user may reasonably expect from the equipment if used as intended.

- Criterion B – During the test, the degradation of performance is allowed. However, no change in the operating state or stored data is allowed to persist after the test. After the test, the equipment shall continue to operate as intended without operator intervention. The performance level may be replaced by a permissible loss of performance. If the manufacturer does not specify the minimum performance level (or the permissible performance loss), then either of these may be derived from the product description and documentation, or by what the user may reasonably expect from the equipment if used as intended.

- Criterion C – Loss of function is allowed, provided the function is self-recoverable or can be restored by the operation of the controls by the user in accordance with the manufacturer’s instructions. Functions, and/or information stored in non-volatile memory, or protected by a battery backup, shall not be lost. For each test method, the test standard specifies the appropriate criterion to be met.

CONDUCTED EMISSION

This test measures the levels emanating from the EUT into the AC Mains, evaluating the potential for the EUT to cause radio frequency interference to other electronic devices. The EUT is configured based upon the requirements of the applicable test standard.

RADIATED EMISSION

This test measures the levels emanating from the EUT, thus evaluating the potential for the EUT to cause radio frequency interference to other electronic devices. Measurement methods are used in accordance with the test standard(s) referenced. The antenna is positioned at several heights while the EUT is rotated 360°. At each antenna height, the receiver scans and records the maximum peak emissions. From the recorded scans, a list of discrete frequencies is developed for that antenna polarity. The antenna is then rotated in polarity and the scan repeated. For each discrete frequency, the turntable is rotated to the determined worst angle and the receive antenna is varied in height from one to four meters for the final maximum emissions. For EUT’s with auto-ranging power supplies, a pre-scan evaluation may be performed to determine “worst-case” radiated emissions.

If Your Buyers Demanding for CISPR 15 Testing – Contact Now!

Kindly send us the following Details, So that we can provide you with a quotation for the same:

- Product Name, Technical Specifications, and Brochure

- Product Images

- Total Number of Samples Required: 2