led lighting standards testing and certification

LED Lights Testing and Certification as Per BIS Standards

LED Lights Testing and Certification as Per BIS Standards in India

Are You Looking for led lighting standards testing and certification in India?

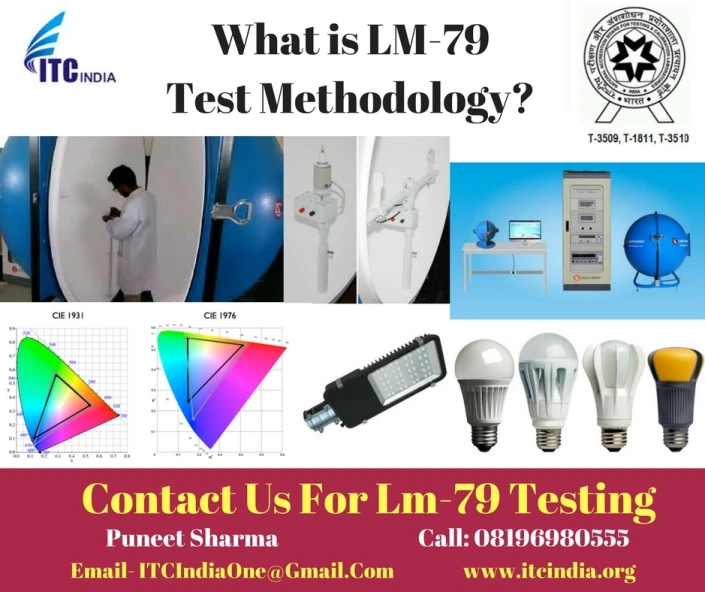

If you are looking for an LED Testing according to BIS Standards in India, ITC India Can Help You! ITC India one of the best BIS LED Lights Testing Service Provider in India. ITCIndia Can do LED Testing as per IEC, EN, ISO, BIS Standard

On this blog, I am not just going to pitch you to hire us for our BIS LED Lighting Testing services but also going to provide a lot of valuable information on what, why and how we can do LED Testing as per IEC, EN, ISO, BIS Standard. Call on 08264401091/ 08196980555 for LED Testing laboratories.

is bis certification mandatory for led lights? Yes Bureau of Indian Standards is mandatory For LED Lighting Testing if you are looking for bis approved led lights testing Labs in India then ITCIndia One of The Best BIS Approved Laboratory, ITCIndia can do led lighting standards testing and certification with reasonable cost.

ITCIndia promises to deliver perfection with every product by its evaluation and assessment techniques designed with a higher degree of professional competence. Along with its existing abilities and a strong quality system, its certifications from the BIS ensure that standardized products have gone under surveillance carried out by qualified professionals only.

BIS (Bureau of Indian Standards ) is a statutory institution established under the (BIS) Bureau of Indian Standards Act, 1986 to promote the harmonious development of the activities of standardization, marking and quality Testing and certification of goods and attending to connected matters in the country.

ITCIndia products have been placed under special Testing and certification schemes check below:

LED testing As per IS 15885 (PART-2/SEC-13):2012

This standard ensures Safety of Lamp Control gear for LED Modules. The control gear specified in this standard is designed to provide constant voltage or current at Safety Extra Low Voltage or (HV) higher voltages. Deviations from the pure voltage and current types do not exclude the gear from this standard.

This includes insulation resistance, electric strength, creepage distances and clearance between primary and secondary circuits, along with:

- SELV Safety Extra Low Voltage control gears

- Auto wound control gear

- Protection against electric shock

- Isolating control gears

- Separating control gears

LED testing As per IS 10322 (PART 5/SEC-1): 2012

This Indian Standard was adopted by the BIS after the draft finalized by the Illumination Engineering and Luminaires Sectional Committee had been approved by the Electrotechnical Division Council. This standard covers the safety and photometric requirements. This series consists of photometric requirements that have been incorporated, that specify requirements for fixed general purpose luminaires for use with a tungsten filament, tubular fluorescent, LED Lights, LED modules and other discharge lamps.

LED testing As per IS 16102 (PART-1):2012

IS 16102 Testing and certification specifies the safety and interchangeability needs, together with the test methods and conditions, required to show compliance of LED Products, LED lamps with integrated means for stable operation, intended for domestic and similar general lighting purposes. This standard ensures that the products cause no danger to the user or surroundings.

ITC India Can Do LED testing as per INDIAN STANDARDS, Hare you can see list of Following Indian LED Testing Standards:

- 16101: 2012 General Lighting – LEDs and LED modules – Terms and Definitions

- 16102(Part 1): 2012 Self- Ballasted LED Lamps for General Lighting ServicesPart 1 Safety Requirements

- 16102(Part 2): 2012 Self-Ballasted LED Lamps for General Lighting ServicesPart 2 Performance Requirements

- 16103(Part 1): 2012 Led Modules for General LightingPart 1Safety Requirements

- 16103(Part 2): 2012 Led Modules for General LightingPart 2 Performance Requirements

- 15885(Part2/Sec13): 2012 Safety of Lamp Control Gear Part 2 Particular Requirements Section 13 d.c. or a.c. Supplied Electronic Controlgear for Led Modules

- 16104 : 2012 c. or a.c. Supplied Electronic Control Gear for LEDModules – Performance Requirements

- 16105: 2012 Method of Measurement of Lumen Maintenance of solid State Light (LED) Sources

- 16106: 2012 Method of Electrical and Photometric Measurements of Solid-State Lighting (LED) Products

- 16107Part 1):2012 Luminaires PerformancePart 1 General Requirements

- 16107-1:2012 Luminaires Performance Part 2 Particular RequirementsSection 1 LED Luminaire

- 16108: 2012 Photobiological Safety of Lamps and Lamp Systems

Testing Advantage From ITCIndia as per BIS STANDARDS :

Achieve worldwide support: by leveraging ITCIndia all over the world reach and expertise in regulations and requirements, regardless of where your lighting products are manufactured or sold.

Save time and money: by identifying compliance considerations at the earliest possible stages of the product development process.

Minimise risks: by testing your lighting products to ensure that they meet all legal requirements for your target markets.

Gain a competitive edge: by delivering lighting products of consistent quality and safety, without compromising time to market.

Benefit from complete solutions: by utilising our full range of testing, certification and auditing services.

Why choose ITCIndia For BIS Testing?

ITCIndia is a leading provider of comprehensive testing services for electrical and LED lighting products. Our global network of technical experts, combined with our state of the art testing laboratories, assure a single-source solution for meeting all applicable requirements, standards and voluntary schemes. And ITCIndia technical professionals are actively involved in international advisory boards and standards development activities, ensuring the most up to date knowledge of current and changing requirements.

Represented in over 5 locations in India, ITCIndia has an unsurpassed track record of meeting and exceeding the requirements and expectations of our client companies. The ITCIndia brand and our distinctive blue octagon mark are instantly recognized around the globe as symbols of quality and safety Testing and will increase customer confidence in your brand.

ITCIndia can assist companies in low-cost life testing and evaluating of their products for pre-compliance and compliance testing to schemes such as The Carbon Trust Enhanced Carbon Allowance

If Your Buyers Demanding for LED Testing as Per BIS – Contact Now!

Kindly send us the following Details, So that we can provide you with a quotation for the same:

- Product Name, Technical Specifications, and Brochure

- Product Images

- Total Number of Samples Required: 2